QForm Forum. Berlin

27—29 May 2019

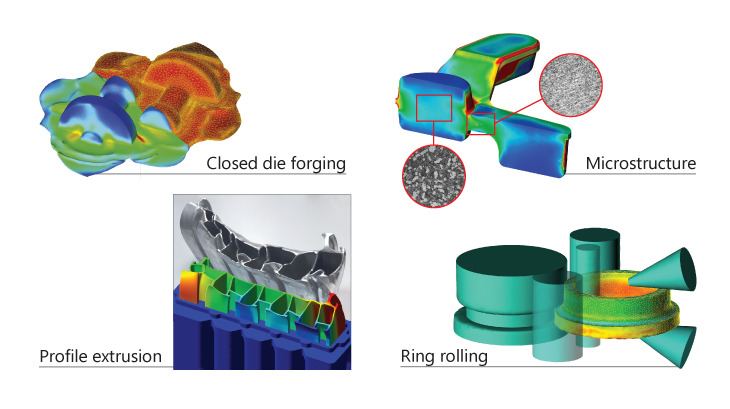

Latest developments in numerical simulation of metal forming

and heat treatment processes

We are glad to invite you to take part in the international QForm Forum which is dedicated to the latest developments in numerical simulation of metal forming and heat treatment processes. The event will be held on 27–29 May 2019 in Berlin, at Pentahotel Berlin-Köpenick. During the forum we will demonstrate a new version of QForm software which got a dozen of new possibilities. Representatives of research institutes and manufacturing companies will give talks about their experience in working with QForm software for development and improvement of technological processes.

Program of QForm Forum 2019

Place: Pentahotel Berlin-Köpenick, Grünauer Straße 1, 12557 Berlin, Germany

Cost of participation:

- Free participation is proposed for speakers

- 350 EURO + VAT for participants

- 250 EURO + VAT for students

- 200 EURO + VAT for accompanying persons (accompanying persons can participate in evening events on 27-28 May)

Recommendation:

For more effective participation in QForm Forum, please, bring your laptop with you to be able to simulate interesting projects in new QForm during event and get new QForm simulation skills.

Contact persons:

Mr. Dmitry Gerasimov

Product manager D/A/CH

QForm Group

[email protected]

Mr. Paul Mordvintsev

Head of Business Development Department

QForm Group

[email protected]

Participate in QForm Forum 2019

QForm Forum 2017. Sergei Stebunov with presentation «Industrial implementation of ring and wheel rolling simulation»

QForm Forum 2017. Sergei Stebunov with presentation «Industrial implementation of ring and wheel rolling simulation» QForm Forum 2017 participants

QForm Forum 2017 participants