The elastic-plastic material model for accurate simulation of cold deformation and forecast of spring back

Simulation of complex tooling sets

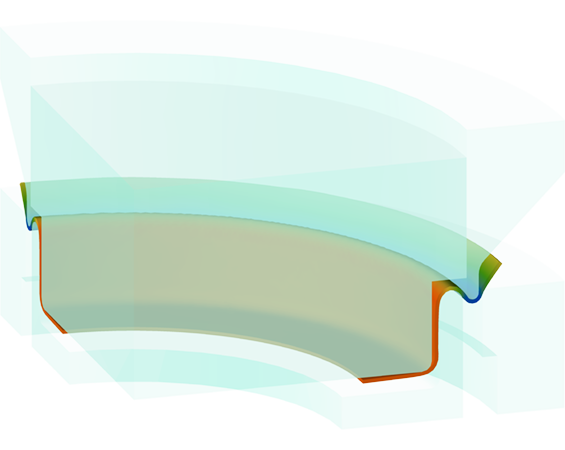

Sheet thickness analysis

Forecasting of destruction by known criteria, such as Cockroft-Latham, Kolmogorov, Verzhbitskiy, etc.

Simulation of a spring-loaded tool with multiple moving forming elements

Final workpiece geometry control

A hexagonal (brick) element mesh is used to model sheet stamping operations. This mesh has significantly fewer nodes, which greatly reduces simulation time without compromising calculation accuracy.

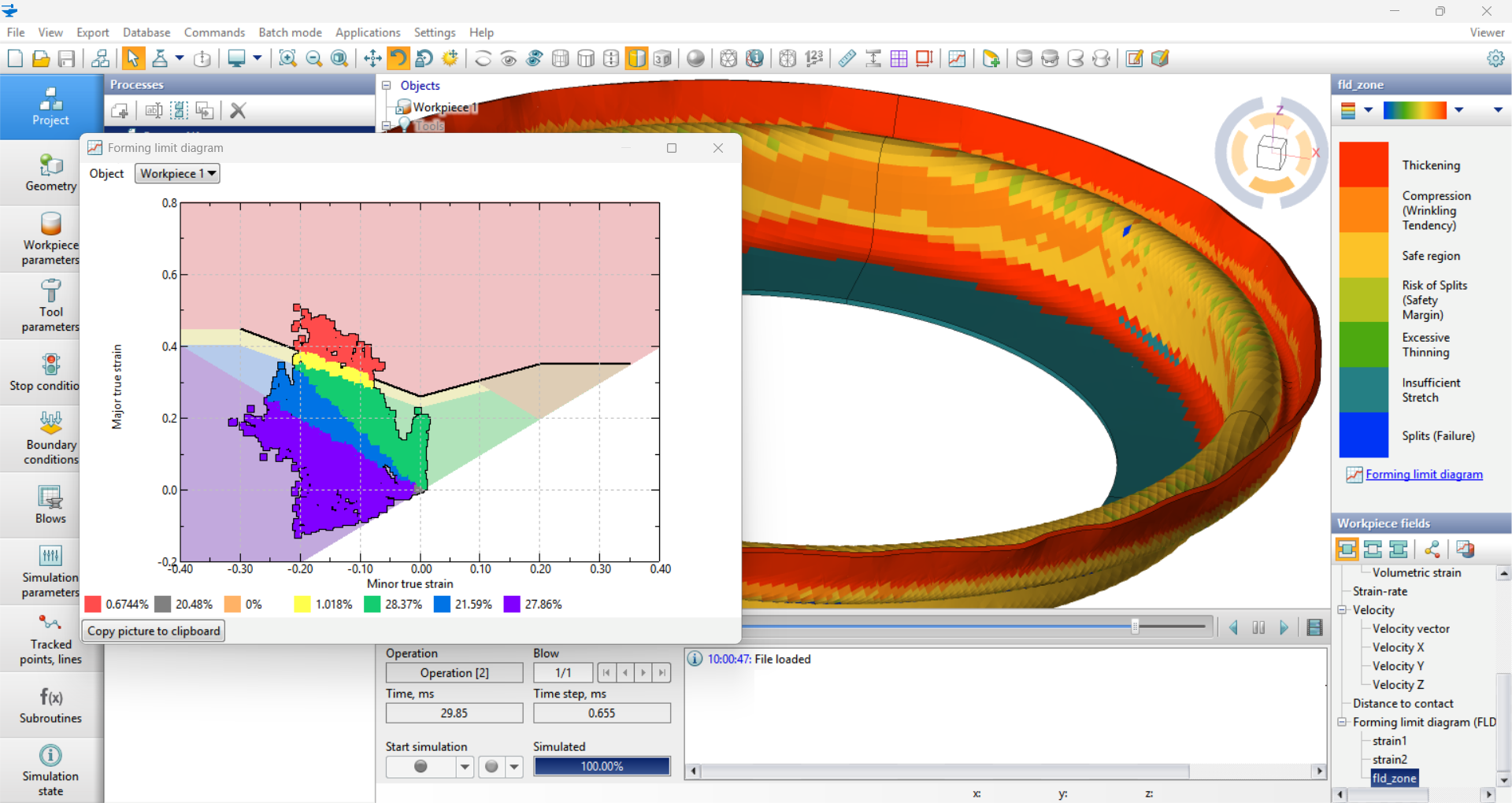

Considering the anisotropic properties of the workpiece helps identify uneven drawing and assess the risk of festoon (wrinkle) formation.

The use of ultimate shape change diagrams (FLD) in calculation algorithms makes it possible to identify ruptures, thinning, thickening, cracks and folds.

A clear example of sheet metal forming simulation is shown in the barrel drawing animation below.

The simulation compares two punch designs - smooth and finned. The smooth punch leads to workpiece failure during forming, while the finned punch with surface microrelief significantly improves performance. This design enhances contact on the lateral surface, enabling a higher drawing ratio and more stable forming.