2025 KSTP

Our distributor, CAE Technology Inc., attended the annual fall conference 2025 KSTP (The Korean Society for Technology of Plasticity and Materials Processing).

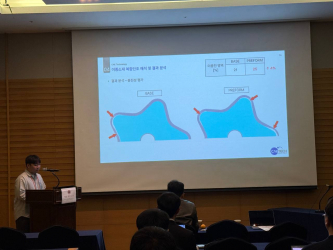

At the conference, they presented a presentation titled “Optimal design of preforming and process analysis techniques for multi-material (AL–STEEL) in composite forging processes”, demonstrating the use of QForm UK Direct for preform forging..jpg)

With the recent rise of lightweight and high-strength automotive parts, multi-material composite forgings combining aluminum and steel are attracting increasing attention. However, forging two materials with different physical and mechanical properties can easily lead to issues such as joint defects and reduced formability.

To address these challenges, this study employed QForm UK Direct to automatically design an optimal preform shape that takes into account aluminum’s flow behavior. QForm UK was then used to perform composite forging simulations, proposing a simulation technique capable of analyzing maximum forming load, underfilling zones, and joint performance during the process.

As a result, the study presents an efficient procedure for designing preforms for multi-material composite forgings and introduces a simulation-based approach for verifying the preform geometry..jpg)

QForm UK Direct is a computer-aided system for automated design of preforming dies for bulk forging. It enables users to create a 3D model of preforming dies for forging operations and import the geometry into QForm UK for verification. QForm UK Direct includes full CAD functionality and uses QForm UK’s calculation algorithms to generate surfaces. Users can refine die geometry directly in QForm UK Direct—adding fillets, holes, and other necessary technological elements. The resulting geometry can be used both in QForm UK simulations and in CAM systems.