Dimensional analysis of the formed part to assess forming quality

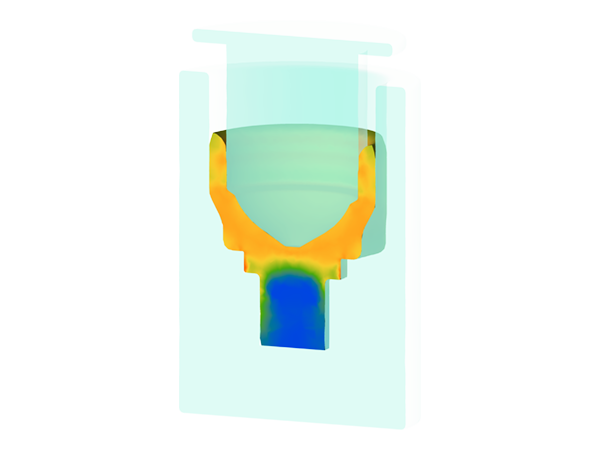

Detection of forming defects, including evaluation based on damage criteria

Prediction of forming loads and verification of cold forming press capacity

Estimation of tool life

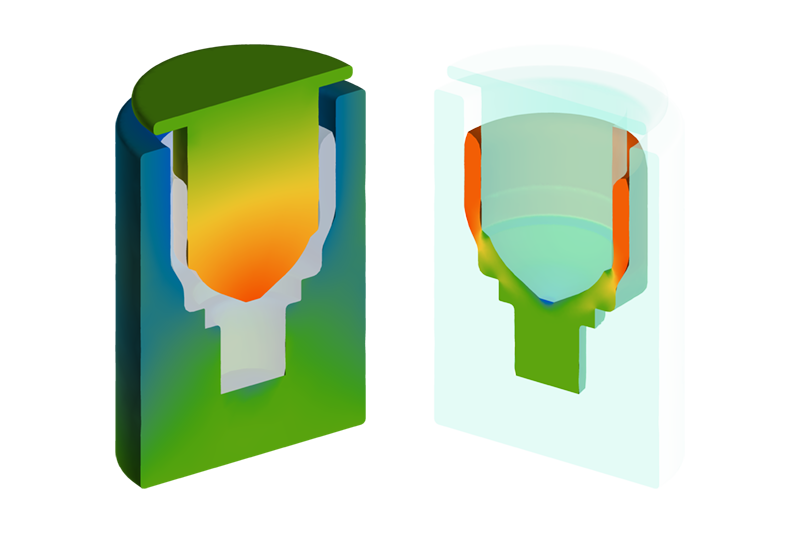

Identification of critical stress zones in dies and punches

Coupled mechanical model – simulates the workpiece and tools as elastic-plastic bodies to accurately reflect deformations under the load.

Thermo-elastic-plastic model – evaluates local thermal stresses for accurate stress and strain analysis in workpieces and tools.

To simulate cold forming accurately, it is necessary to use rheological models of materials that were tested at cold forming temperatures (in general 20 – 400 degrees Celsius). It is possible to implement criteria such as Cockcroft-Latham, V.L. Kolmogorov, Wierzbicki, Del, Johnson & Cook, McClintock, Rice and Tracy, V.A. Ogorodnikov, Yu.G. Kalpin in QForm to evaluate fracture defects in cold forming simulations.

QForm accurately predicts the location of laps at all stages, matching real-life defects. The simulation also reveals high effective stresses in the punch, indicating potential tool failure, which is confirmed by the actual broken tool shown at the end of the video.