General Metal Forming simulation is the core software for the simulation and optimization of metal forming processes. It forms the foundation of the QForm system and supports a wide range of forming operations within a unified simulation environment.

The module provides universal thermo-mechanical simulation capabilities and can be greatly expanded with specialized QForm modules to address specific process requirements, including:

Extrusion

Rolling

Sheet metal forming

Microstructure evolution

Heat treatment simulation

And other advanced forming technologies

This modular architecture allows users to combine general-purpose forming simulation core with process-specific features, enabling accurate prediction of material flow, temperature distribution, forces, defects, and final part properties across different manufacturing stages.

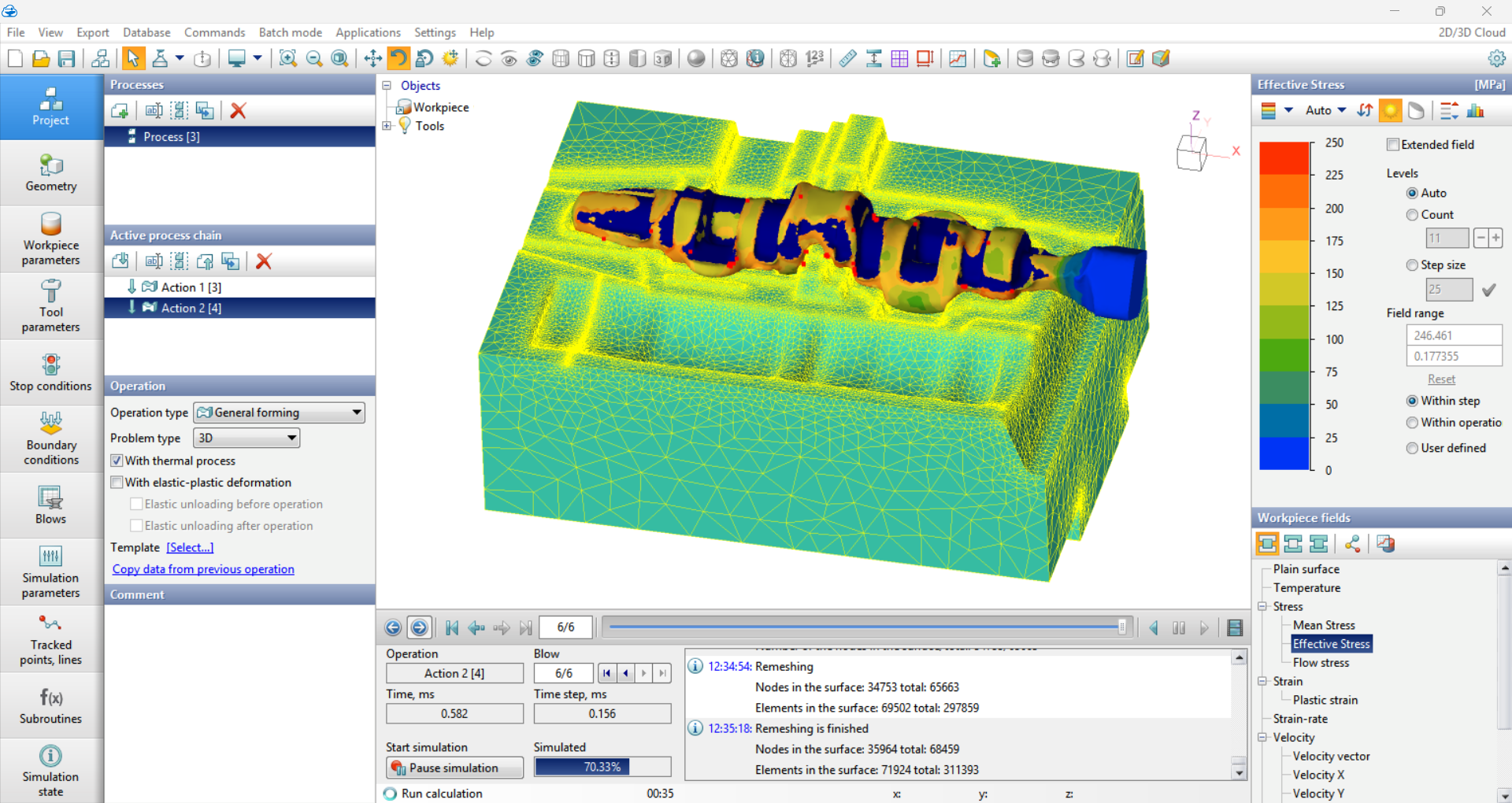

The new algorithms enable highly efficient use of modern multicore processors and system resources, delivering substantially faster simulations. Because the solver and user interface operate separately yet concurrently, results can be displayed in real time, even during complex simulation runs.

Users can set initial parameters, control the simulation process, and analyze results within a single, integrated interface. A wide range of tools helps users easily define complex technological processes and conveniently explore the extensive data generated by the simulation.

The creation of the finite element mesh and the rebuilding of the mesh during simulation are performed automatically and, as a rule, do not require user involvement.

Using subroutines and APIs, QForm helps avoid routine tasks and saves valuable time for specialists, freeing them for creative problem-solving. Simulation results can be presented in an easy-to-understand format using automatically generated templates customized to your company’s standards.

Before implementation of the QForm software the initial forging technology had a flow-through defect. The exact location of the defect was identified by the simulation. The under-surface flow lines in QForm show this defect which is marked out on the photo presented in this video.

By means of the simulation it was easy to understand the reason of defect formation. Then the central part of the die impression was modified to escape the defect. The comparative analysis of the initial and optimized tool geometry is shown in the video.

The second part of the video shows the simulation results for the optimized technology where the defect is not appeared.

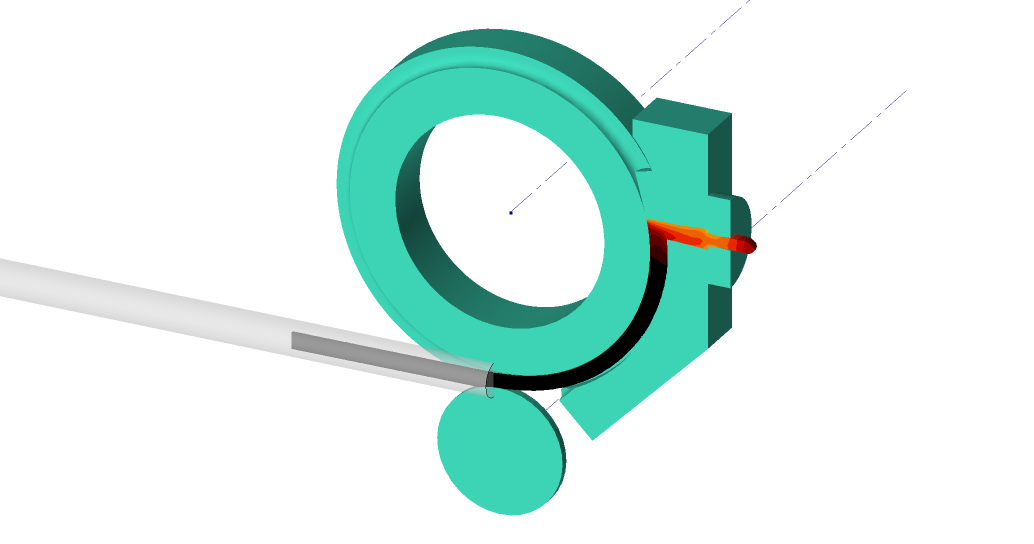

Orbital forming is a metal forming process in which a tool rotates on an inclined axis, applying localized deformation to the workpiece. Unlike conventional forging, only a small contact area is deformed at any moment, which significantly reduces forming force and energy consumption.

QForm enables accurate simulation of orbital forming processes and takes into account:

Incremental plastic deformation caused by the rotating and oscillating tool

Complex tool kinematics, including inclined-axis rotation and orbital motion

Contact and friction conditions between the tool and the workpiece

Material flow and strain accumulation, allowing prediction of final geometry and internal structure

Force and torque evolution during forming, useful for machine selection and process control

Using QForm, engineers can analyze stress–strain states, identify zones of excessive deformation, and evaluate the risk of defects such as surface cracking, laps, or incomplete forming.

Lower forming forces compared to conventional forging

Improved dimensional accuracy and surface quality

Optimization of tool geometry and motion parameters

Reduced experimental trials and tooling costs

Conform (Continuous Rotary Extrusion) is a solid-state continuous extrusion process in which a feedstock (rod or wire) is driven by a rotating grooved wheel and forced through an abutment into a die, producing a continuous profile without billet replacement.

QForm simulation of the Conform process accurately takes into account:

Heat generation, which is critical for predicting the self-heating behavior and steady-state temperature regime of the process

Material feeding, accumulation, and redirection through the die

Continuous extrusion conditions, with no billet change, allowing analysis of transient and steady-state stages of production

Thermo-mechanical behavior of aluminum and copper alloys, including temperature-dependent flow stress, strain hardening, and thermal properties

Using QForm, engineers can predict material flow stability, temperature distribution, extrusion forces and torque, and assess the risk of defects, enabling optimization of process parameters and tooling design before industrial implementation.

Prediction of torque, force, and power requirements for proper machine selection

Early detection of potential defects

Optimization of tool geometry and process parameters

Reduction of trial-and-error and production costs

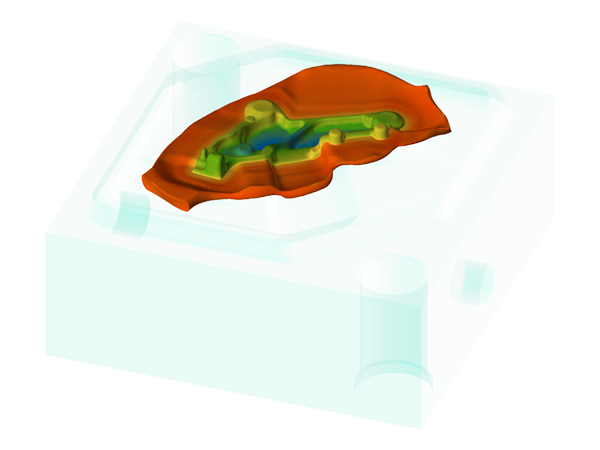

Hydroforming is a metal forming process in which a tube or sheet blank is shaped inside a closed die using high-pressure fluid. The process enables production of complex, lightweight components with smooth surfaces and uniform wall thickness, widely used in automotive, aerospace, and structural applications.

QForm provides a fully coupled thermo-mechanical simulation of hydroforming processes and takes into account:

Material plastic deformation under internal fluid pressure, including large strains and complex stress states

Interaction between the workpiece and the die, with accurate contact and friction consideration

Internal pressure and axial feeding control, allowing analysis of different loading paths

Thickness distribution and thinning prediction

Risk of defects, such as excessive thinning, wrinkling, and insufficient forming

QForm supports simulation of tube or sheet hydroforming, enabling engineers to optimize pressure-time curves, axial feed, and tooling geometry before physical trials.

Reduced trial-and-error during process development

Improved part quality and thickness uniformity

Accurate selection of process parameters and equipment

Lower tooling and production costs