Material flow prediction depending on tool shape, rotation and/or axial movement between blows

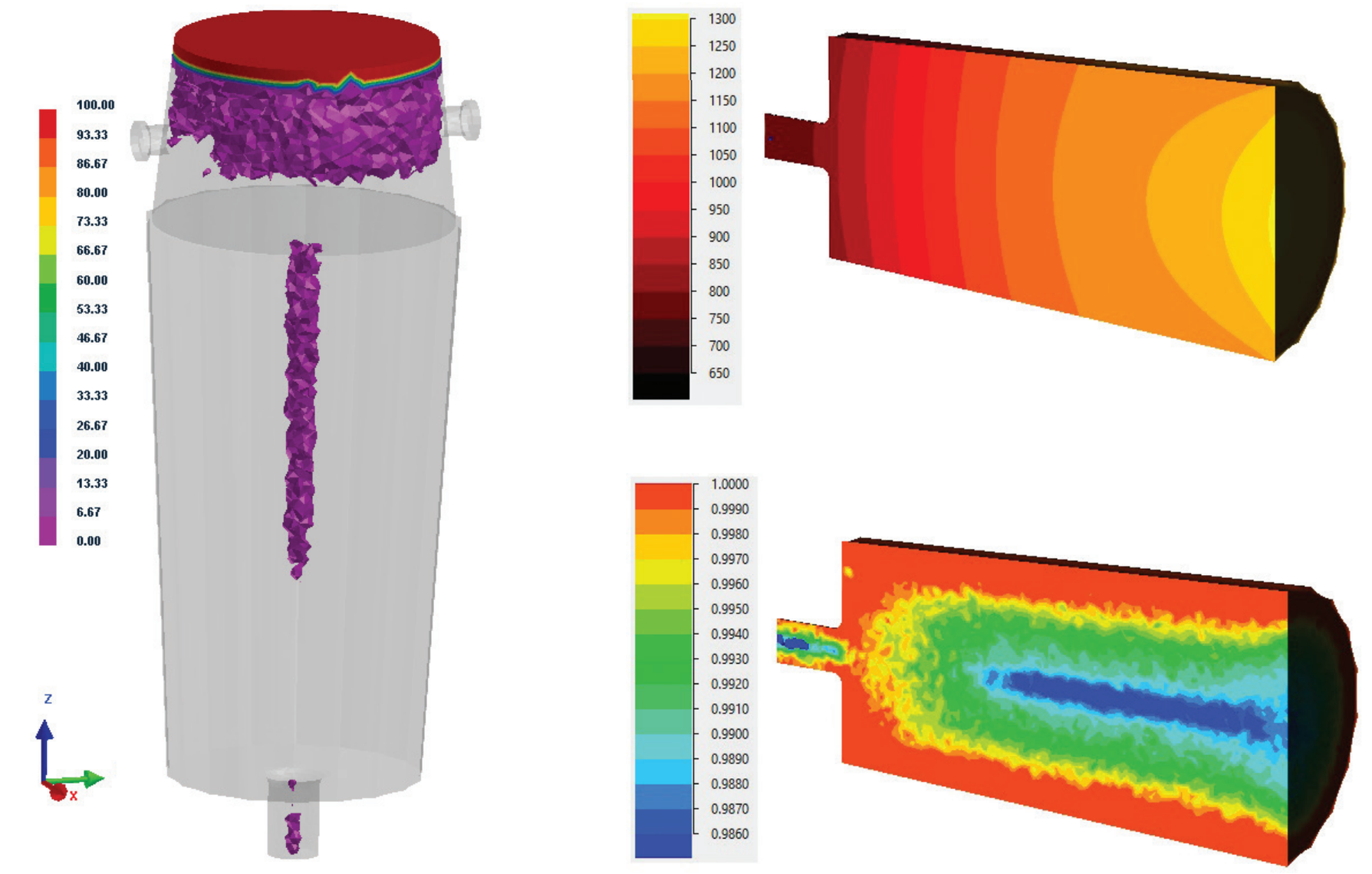

Calculating thermo-elastic-plastic stresses during heating and cooling to predict the possibility of cracks

Possibility to predict macro and microstructure on the computer during development of the process

Simulation of complicated regimes of heating and cooling, necessity of inter-operation heating

Possibility to predict changing of axial billet porosity during forging of cast billet

Specialists require reliable tools for complex technological processes in which workpieces are extremely large and costly, and the risk of incorrect process design is high. For this reason, simulation is essential for open-die forging of large billets weighing tens and hundreds of tons.

The QForm simulation chain presented in this video includes not only the simulation of the open-die forging process itself, but also the associated thermal cooling and reheating stages, providing a comprehensive and realistic representation of the entire technological cycle.

Prediction of structure quality after forging of the cast billet and estimation of surfaces and inner defects, thanks to importing of shape and calculated fields from casting simulation software (e.g. Procast, MAGMA)

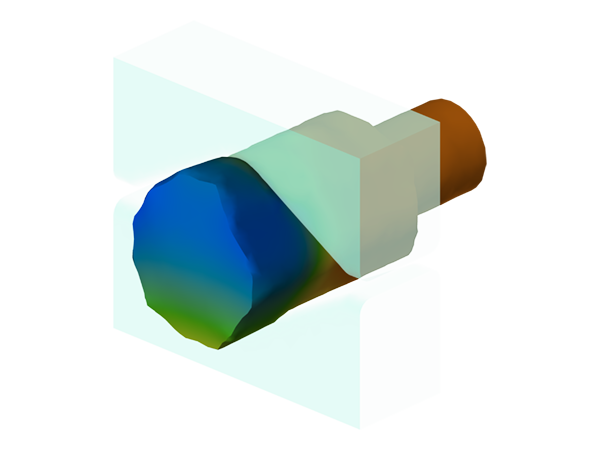

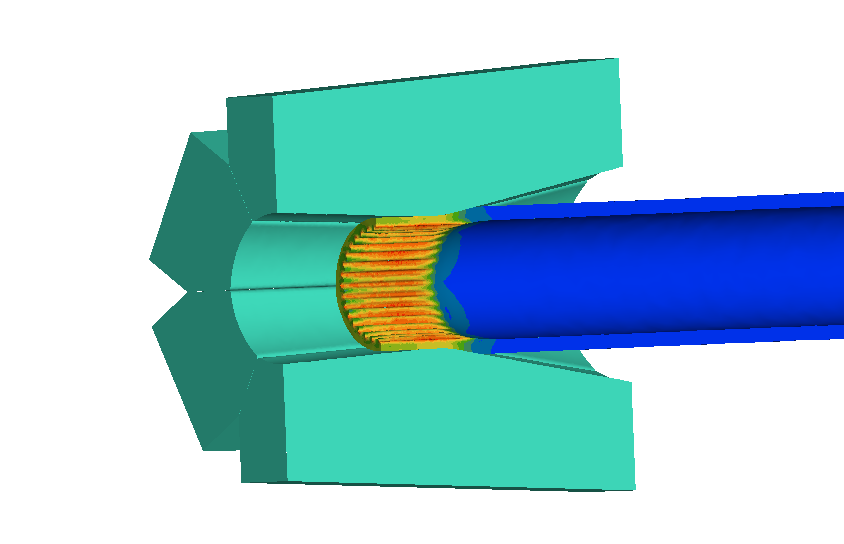

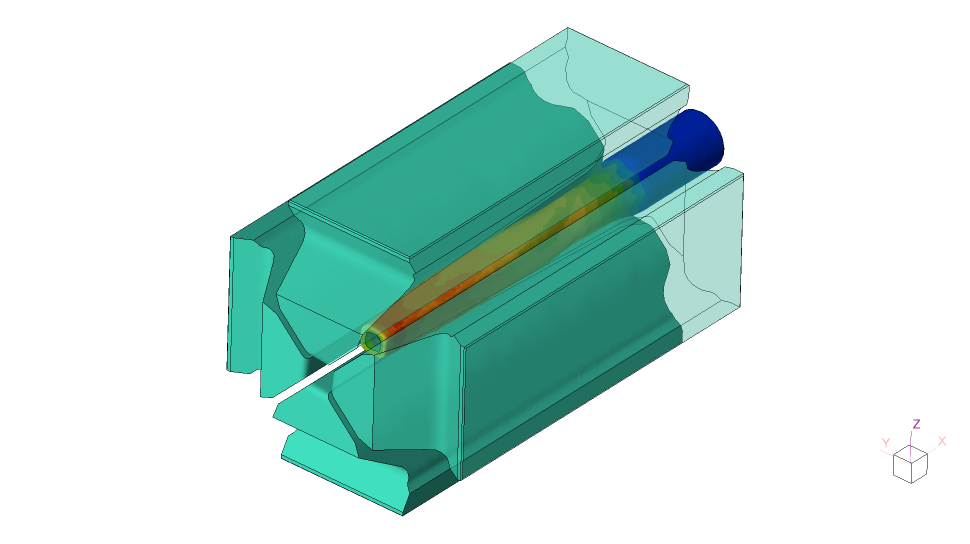

The process of rotary swaging utilizes two to six dies for radial forming while the workpiece is moved axially forward and/or backward. The dies may perform up to 10000 strokes per minute and their displacement might be as little as 0.2 mm per stroke.

A relatively short simulation time with a local deformation zone due to implementation of specific dual mesh algorithms

Prediction of material flow during the whole forging process

Determination of the number of strokes, feed and rotation values for set up of the technological process in the press

Prediction of the fibrous structure into the volume of the workpiece

Identification of defects into the volume of the forged piece

Simulation of the stress-strain state with calculation of the die wear and tool life

The process of rotary swaging utilizes two to six dies for radial forming while the workpiece is moved axially forward and/or backward. The dies may perform up to 10000 strokes per minute and their displacement might be as little as 0.2 mm per stroke.

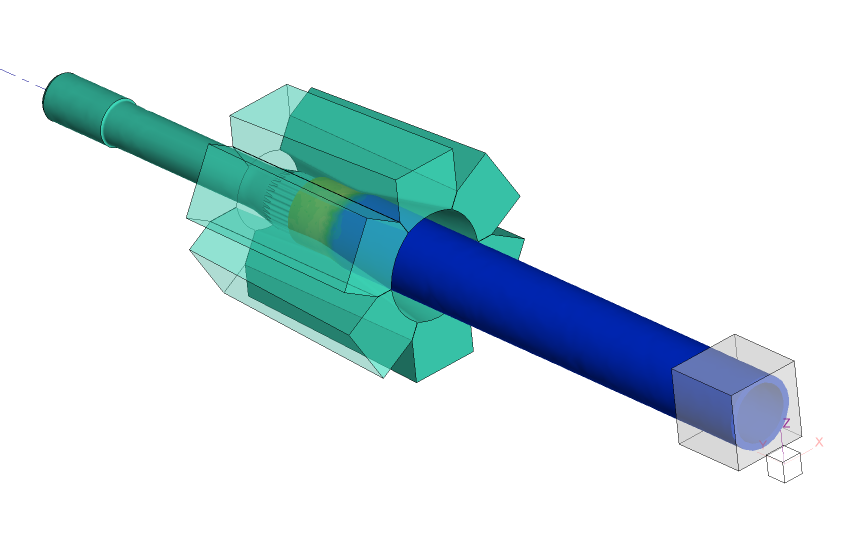

Ring forging process is interesting because the workpiece rotates after each deforming tool stroke.

Special features of QForm allows simulation of such a process in one operation.