QForm simulates a wide range of rolling processes using multiple deforming tools with different axes of rotation.

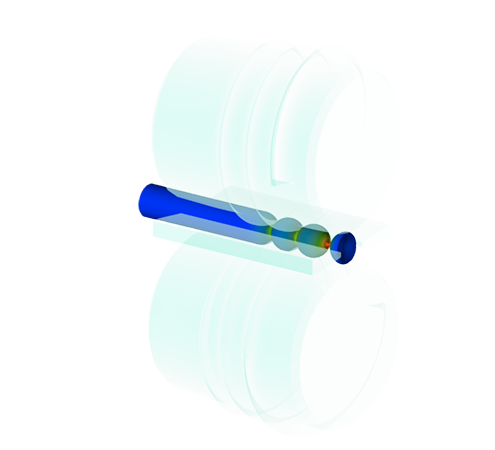

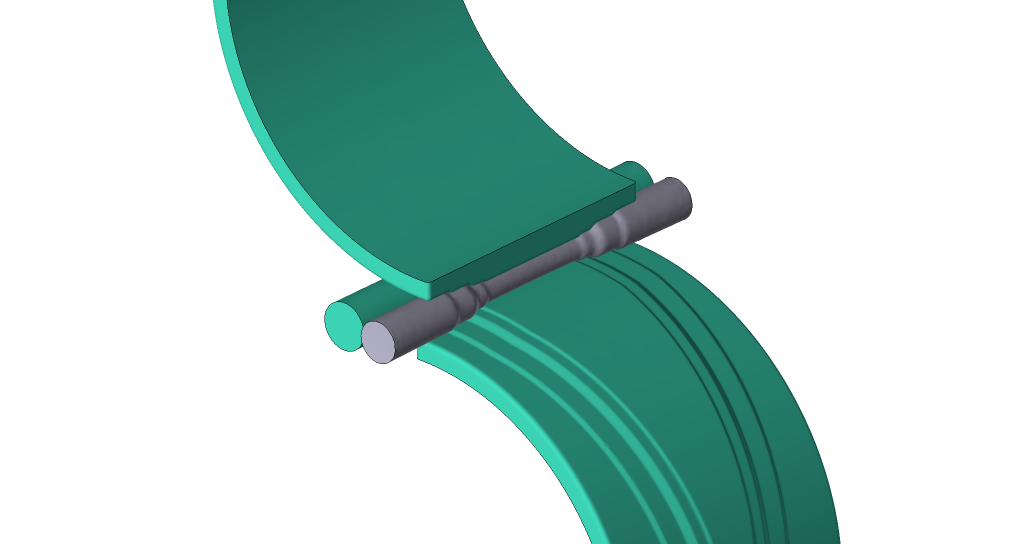

Cross rolling is an economical and effective way to produce preforms with variations in cross section diameters. The process rolls the workpiece between rotating dies to create various diameters across the length of the workpiece. Designing tools for cross-wedge rolling is a very difficult and intensive process, and production of these tools is expensive. QForm software significantly reduces the time and cost for designing and realization of this technological process. QForm allows simulation of the entire process chain including cross-wedge rolling as preforming operation and subsequent forging operations. Simulation of this preform process is the only way to insure the best accuracy in subsequent forging operations.

.png)

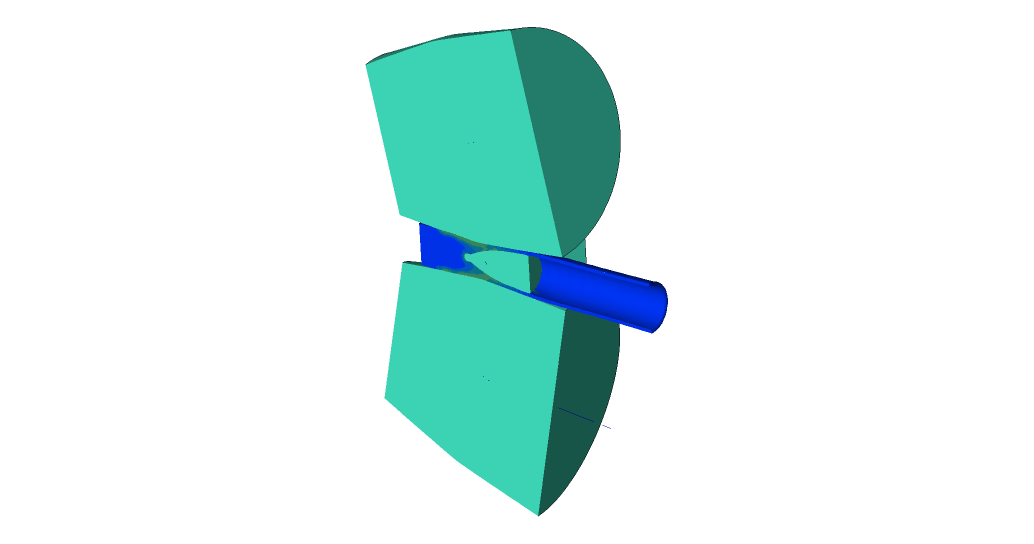

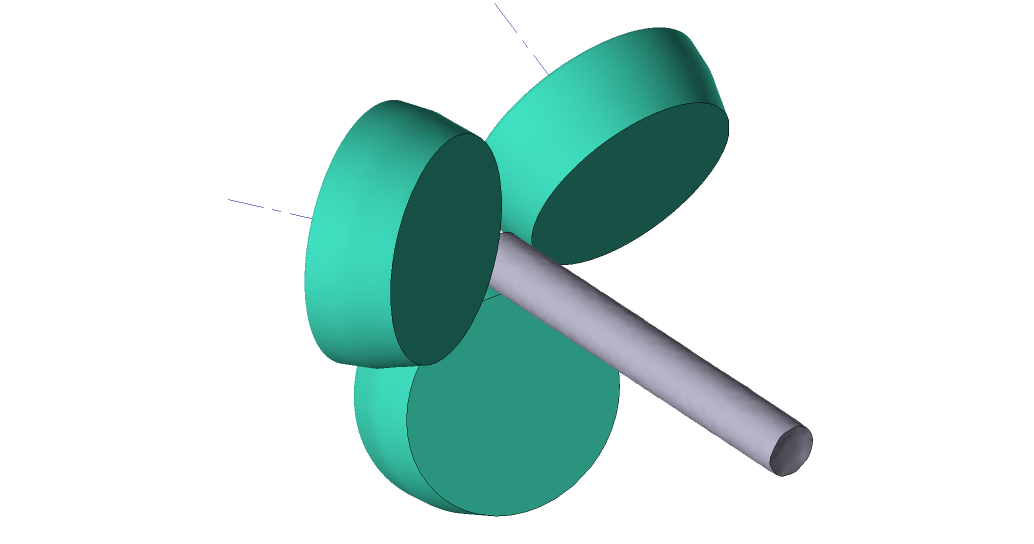

Cross-roll piercing and cross helical rolling are incremental processes where localized deformation moves along the rotating workpiece to shape the entire volume. Such incremental processes are the most complex for simulation and impose specific requirements for the core of solvers and finite element mesh generator:

A special mesh is required in the moving plastic deformation zone

Volume constancy is required throughout the deformation process

An acceptable simulation time must be provided while ensuring an accurate calculation

Consideration for building finite element mesh in a rotating workpiece body

A good stress-strain state in the deformation zone can be achieved during cross-roll processes, which allows production of pipes and rods with uniform macro and microstructure in the cross-cut section for good mechanical properties of the rolled parts.

A characteristic feature of cross-roll piercing (rotary tube piercing) is that metal continuity failure occurs after some reduction of the diameter and this crack propagation forms the cavity in the central part of the workpiece. It is possible to identify the formation of the cavity and the zone where ductile fracture is occurring by estimating the stress-strain state using the QForm software with the implementation of fracture criteria. It is important to establish whether the formation of cavities happens as the result of brittle metal fracture or severe plastic deformation of the workpiece core under the influence of shear stresses (ductile failure).

The QForm software fully meets the requirements for simulation cross-roll piercing and cross helical rolling

Technological process and reducer rolling tool designing is a very difficult and complex task therefore the tool designs require verification. The use of QForm eliminates costly reducer rolling trials and tool modifications, and therefore lowers the cost of rolling process tooling.