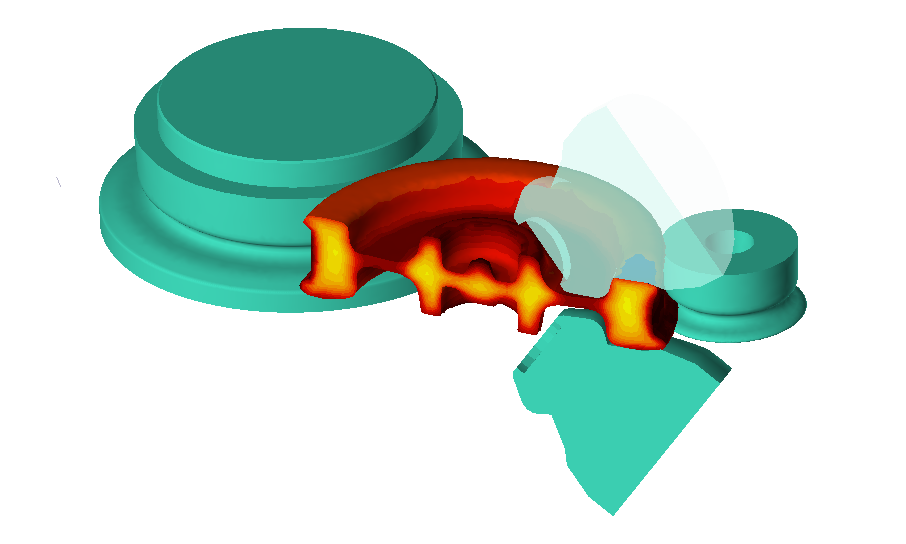

Final shape and defects presence prediction

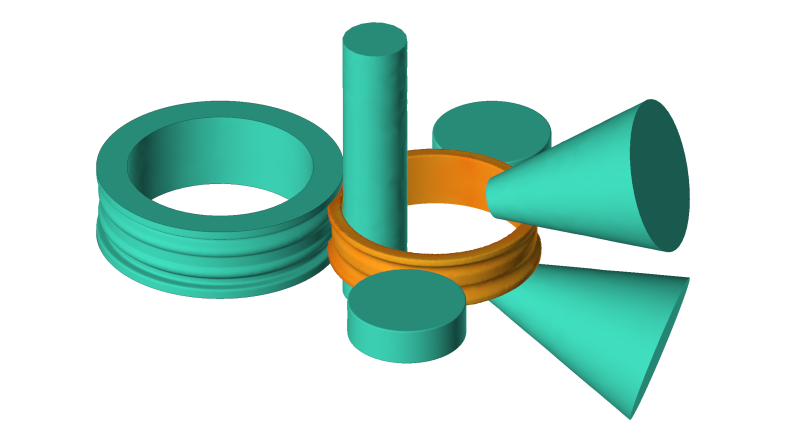

Calculation of load and torque in all tools

Calculation of load gradient, wear and deflections of the tools

Monitoring temperature and detecting out-of-range zones

Evaluation of rolling curves and strategies: analysis of ring growth speed versus diameter, and height variation versus thickness

Grain flow quality prediction using flow line tracing from preforming to final rolling

Evaluation of optimal rolling regimes

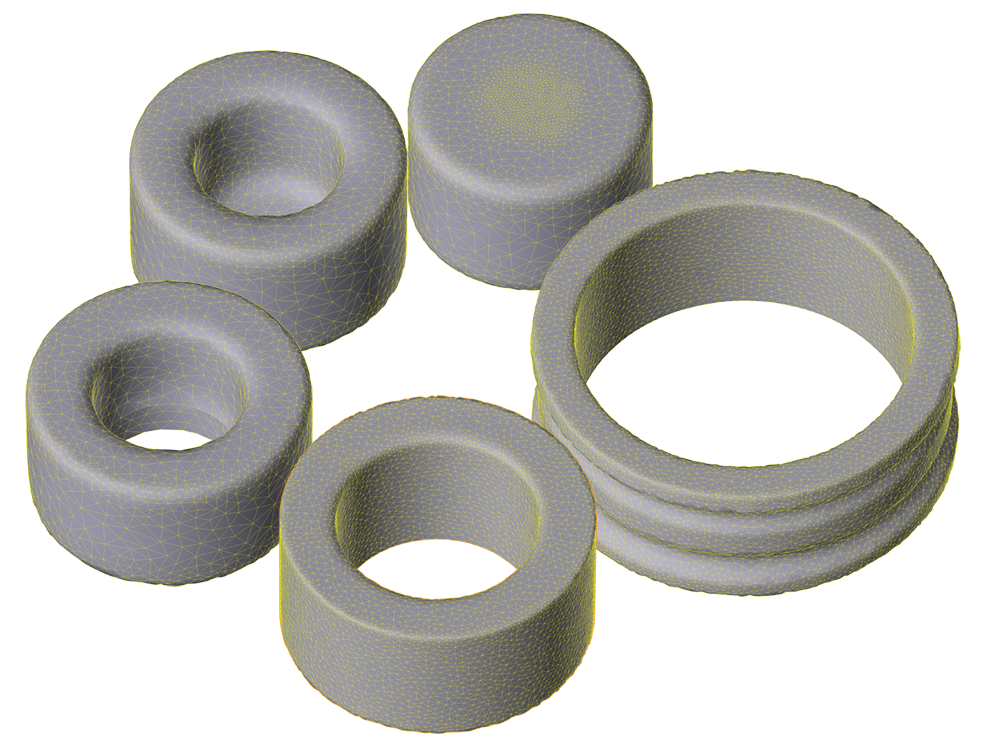

The software supports various machine types: radial, radial-axial, wheel rolling, and frame (case) configurations. Users can simulate the entire technological chain, from initial workpiece heating to preforming, punching, and final rolling, enabling comprehensive process analysis in one platform.

QForm Ring and Wheel Rolling allows users to define rolling curves and strategies based on widely used rolling machines, including SMS Meer, Muraro, Siempelkamp, Mitsubishi etc.

QForm Ring and Wheel Rolling includes a specially developed, fully automated dual mesh algorithm that significantly increases the speed of simulations for incremental processes. A dedicated meshing algorithm also provides highly densified mesh in tool contact zones with the workpiece, greatly improving simulation accuracy without adding to computation time. These features ensure both precision and efficiency during complex simulations.

The following technological tasks are solved in QForm software during simulation of ring and wheel rolling processes:

Control of temperatures within the process and checking for locations that exceed the specified temperature range of steel deformation for the entire technological process chain

Prediction of grain flow quality in ring or wheel thanks to lines tracing from the preforming operation through the final rolling operation

Evaluation of rolling curves and strategies: dependence of ring growth speed from diameter and dependence of height from thickness

Evaluation of optimal rolling regimes

Rolling of railway wheels is the most widely used manufacturing process. QForm simulation makes it possible to predict the final wheel geometry with high accuracy, analyze metal flow and temperature distribution, identify potential defects at early stages, and optimize process parameters. As a result, numerical simulation reduces the number of physical trials, lowers production costs, improves product quality, and ensures reliable evaluation of loads and torques acting on all tools.