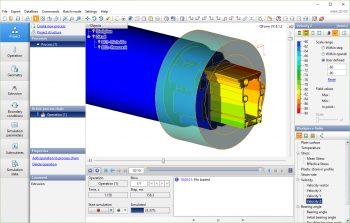

QForm UK Extrusion

QForm UK Extrusion is the only program in the market that can perform simulations of material flow that are thermally and mechanically coupled to the die deformation even for very complicated thin walled profiles.

QForm UK Extrusion was developed for simulation analysis of material flow during the extrusion process and for analysis of the stress-strain state of die set. The program features parametric representation of the bearing geometry and state-of-the-art automatic meshing algorithms. By keeping the bearing geometry as a parametric surface, QForm UK Extrusion is able to consider cases when die deformation causes local zones of very fine inclination of choke or relief that may vary by just a few angular minutes. Simulation results and actual production of our customers as well as laboratory tests have shown that, though small, such bearing angle variation may significantly influence the material flow patterns. The software has been developed to be used by production engineers and die designers so it is not necessary to know anything about finite element method to run accurate simulations.

I have been using QForm UK for a little over 6 months, and I have been very happy with the results that I have gotten. I found the software very easy to use. The average pre-processing time is around 15 minutes... The tech support has been very helpful and very quick with getting me help and any information that I have needed. The results from simulation have been very accurate... Our company as whole has been happy with the purchase of QForm UK.

Jeff Skinner, Simulation tech and R&D, Gemini Group.

The tools for complex extrusion profiles can take a long time to design properly. The use of simulation software significantly speeds up the development time of extrusion tooling, eliminates trials in real press, significantly shorten the time to market, predicts the quality of the extruded product and by these means drastically reduce production cost.

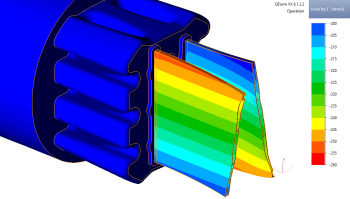

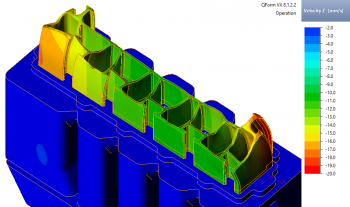

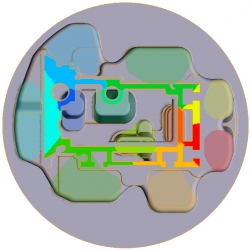

Profile velocity along Z axis. Thin hollow profile

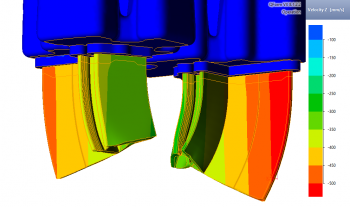

Profile velocity along Z axis. Thin hollow profile Profile velocity along Z axis. Hollow profile

Profile velocity along Z axis. Hollow profile

ASAŞ Extrusion implements an innovative approach to extrusion technology development that improves final production quality and decreases manufacturing costs. Prior to manufacturing the die and extrusion trials we analyze each profile extrusion process using QForm UK software to predict and eliminate defects and problem areas that can occur during real extrusion.

ASAŞ.

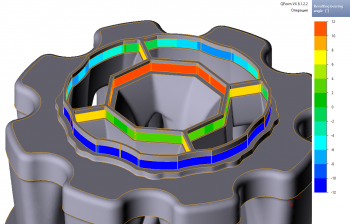

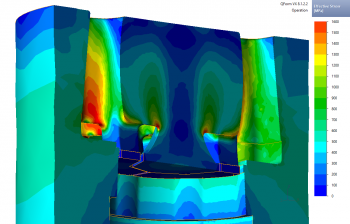

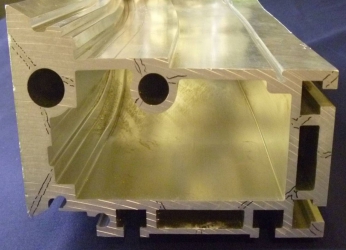

Resulting bearing angle due to die deformation

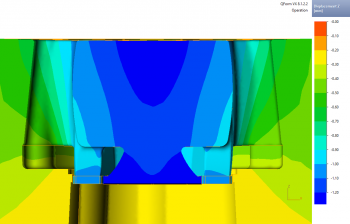

Resulting bearing angle due to die deformation Die deflection

Die deflection

Advantages of QForm UK Extrusion:

- Simulation of mechanically and thermally coupled problems of material flow and die deformation (taking into account influence of die deflection on material flow and vice versa)

- The fastest simulation speed (ICEB 2015) of the most complicated profiles thanks to a special Lagrange-Euler approach and advanced algorithms used in QForm UK

- Simulation of profile elastic-plastic deformation due to cooling after extrusion

- Very accurate results of simulation thanks to high adaptive tuning of the mesh and a specially developed coupled mechanical and thermal tasks

- An intuitive interface and easy input of initial data allow for a short learning curve

- Fully automatic simulation process

- View and analysis of results of the simulation during calculation process

5th International ICEB Conference. Industrial benchmark. Profile velocity along Z axis.

5th International ICEB Conference. Industrial benchmark. Profile velocity along Z axis.  Profile velocity along Z axis. Construction profile

Profile velocity along Z axis. Construction profile

Features of QForm UK Extrusion:

- Simulation of solid, semi-solid and hollow profiles of any complexity

- Profile front end shape prediction

- Profile velocity destribution on the any stage of the process

- Coupled mechanical and thermal task calculation for any number of billets

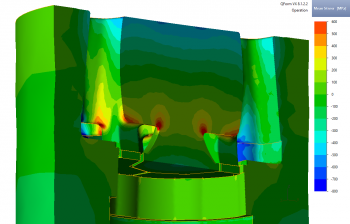

- Taking into account influence of die deflection on material flow and vice versa

- Temperature, stress, strain, velocity distribution in any cross cut section of the workpiece and tool

- Die life prediction

- Determination of profile distortion due to die deflection and after cooling

- Prediction of extrusion load

- Bearing height optimization

Effective stress in die

Effective stress in die Mean stress in die

Mean stress in die

- Longitudinal seams weld prediction (meterial streams borders)

- Charge weld seam length prediction (billet to billet seam weld)

- New material share percentage in profile versus the distance from stop-mark or the ram displacement

- Accurate calculation of entire billet heat gradient

- Fully automatic mesh generation and highly adaptive mesh in material flow domain and tool simulation domain

- User defined subroutines calculation

- Tracing of the points

- Report generation

Longitudinal seam welds. Exactly the same picture as in the simulation

Longitudinal seam welds. Exactly the same picture as in the simulation 5th International ICEB Conference. Industrial benchmark. Longitudinal seam welds

5th International ICEB Conference. Industrial benchmark. Longitudinal seam welds

QForm UK Extrusion has successfully participated in all the independent international benchmarks (The International Conference on Extrusion and Benchmark (ICEB)) since 2005:

- Benchmark 2015, ICEB, Florence, Italy

- Benchmark 2013, ICEB, Dortmund, Germany

- Benchmark 2011, ICEB, Bologna, Italy

- Benchmark 2009, ICEB, Dortmund, Germany

- Benchmark 2007, ICEB, Bologna, Italy

- Benchmark Extrusion 2005 Zurich, Switzerland