Recrystallization analysis

Control of grain growth and coarsening of structure

Evaluation of grain grade according to international standards

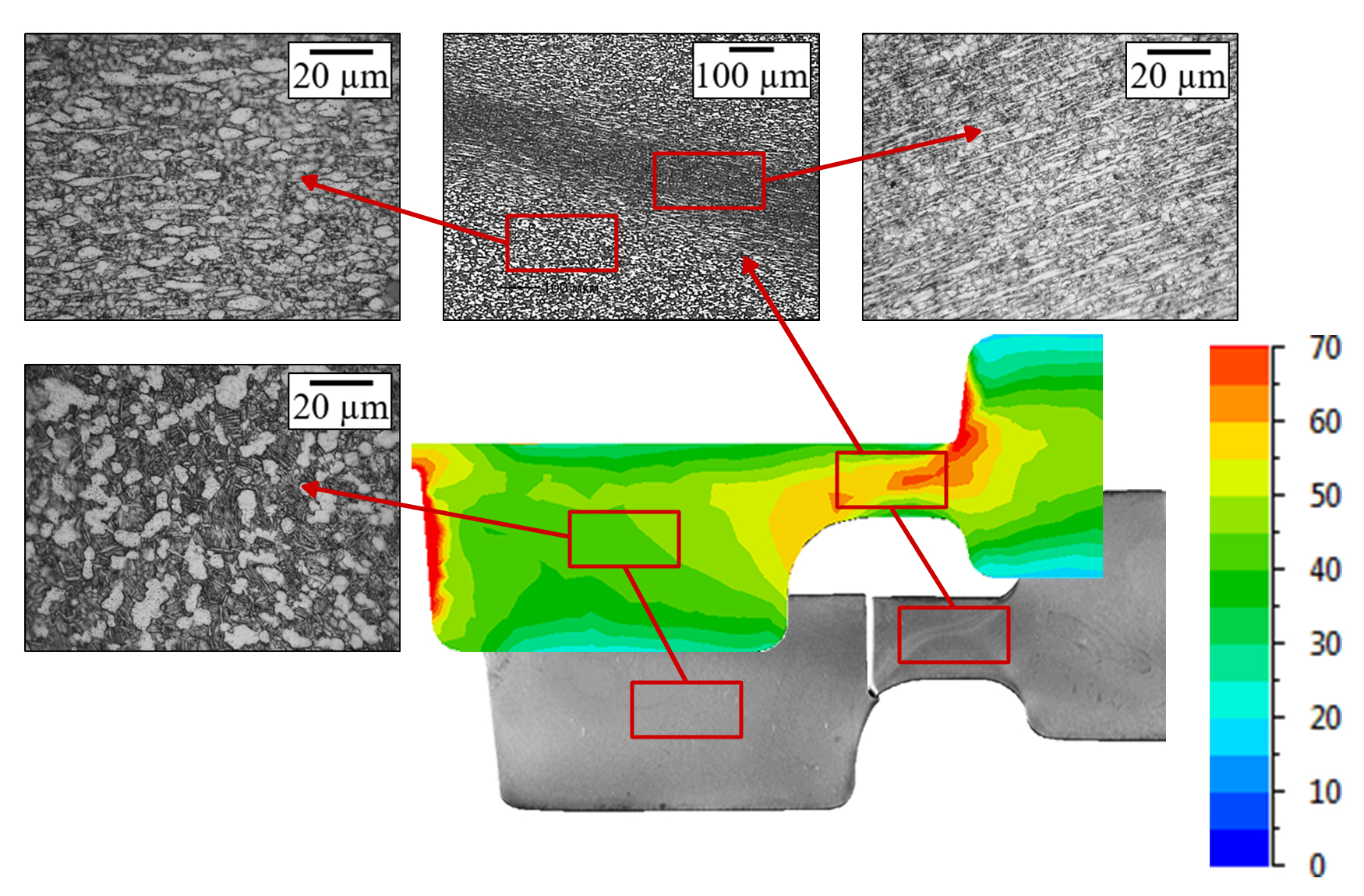

Determination of microstructure evolution type

Calculation of the process chain heating-deformation-cooling

Advanced material database

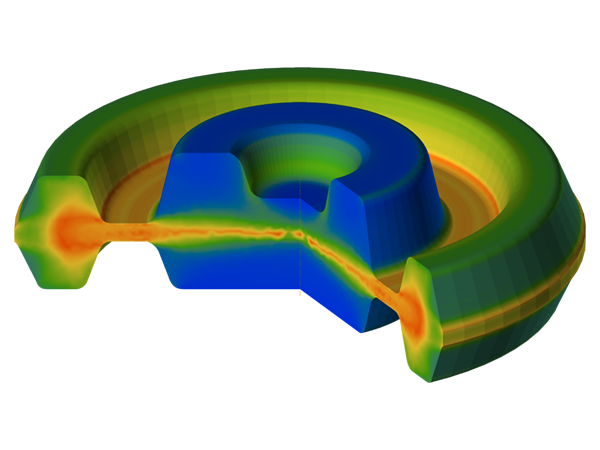

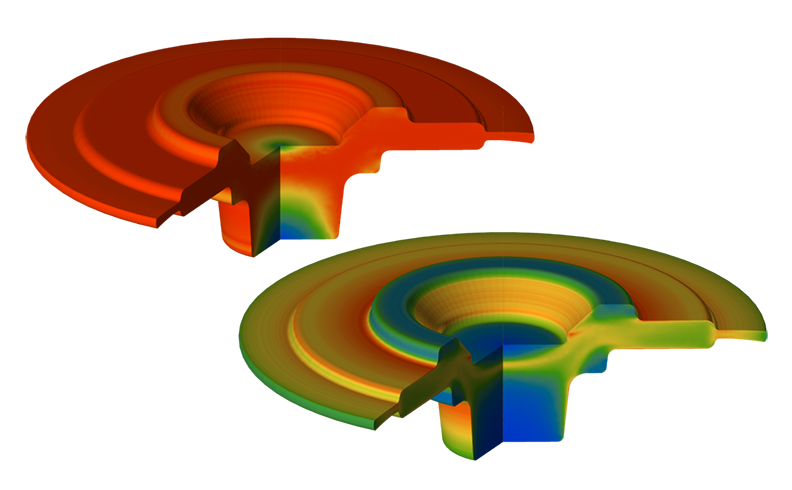

The calculation takes into account the influence of temperature on the coefficients of the model, as well as the cyclic recrystallization. The module can perform end-to-end calculations of microstructure evolution in the process chain with inheritance of calculation results and works for both 2D and 3D problems.

This module enables users to analyze and fine-tune thermomechanical processing parameters, including:

Deformation Mode Optimization – Adjust strain conditions to achieve the desired microstructure and mechanical properties

Thermal Cycle Planning – Select optimal temperatures, dwell times, and heating durations to prevent grain growth and microstructure coarsening

The module calculates a comprehensive set of parameters related to recrystallization and microstructure evolution, including:

Volume fraction and average grain size for dynamic, static, and metadynamic recrystallization

Total recrystallized volume and ASTM grain number

Microstructure evolution type and retained strain

Critical deformation and initial grain size before each cycle

Number of recrystallization cycles (if cyclic mode is enabled)

Reference fields such as deformation time, average temperature, strain rate, dwell time, and grain growth duration

These results provide deep insight into material behavior during thermomechanical processing.

Both processor and postprocessor regimes of microstructure simulation are available in QForm. The results of the calculation are shown in the workpiece fields.