Fast simulation of various heat treatment variants to optimize cooling and heating conditions of a part in order to ensure the required properties, minimization of distortion and heat treatment time, energy-efficient production

Prediction of properties of finished forged pieces after heat treatment (hardness, ultimate strength)

Quenching cracks prediction option

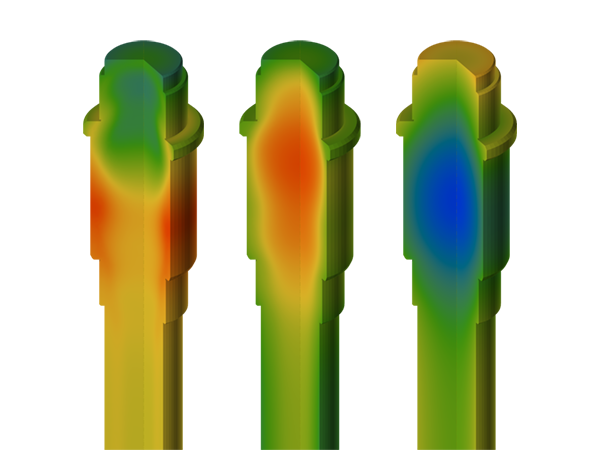

Determination of the phase composition of a part

Evaluation of residual stresses and distortion after the heat treatment

The module supports flexible temperature profiles and sequences, allowing simulation of processes such as solution treatment, various quenching methods (interrupted, stepped, spray, isothermal, subcooling, self-tempering), tempering, and aging — including complex multistage treatments.

Simulation evaluates thermal stresses and distortion during heating and cooling, enabling assessment of cracking risks and precise prediction of the final forged part shape.

The Alloy Generation Assistant is designed for convenient input data setting: phase properties, phase transformation kinetics, latent heat, volume change coefficients during phase transformations, equilibrium volume fractions of phases. It is also possible to import material properties from other programs and reference books, such as JMatPro for low-alloy and carbon steels.

distribution in the connecting rod.jpg)

distribution after quenching. Bainite and martensite phases are shown.jpg)