QForm UK is a universal program trusted and widely used by researchers, scientists, industrial engineers, and technical specialists. By using accurate numerical simulation, users can predict material flow, final geometry, defects, loads, and process limits at early design stages. This significantly reduces the need for costly physical trials, shortens development time, improves product quality, and increases tool life. Various metal products developed with the help of QForm UK are now used in components and systems that form an integral part of our everyday life.

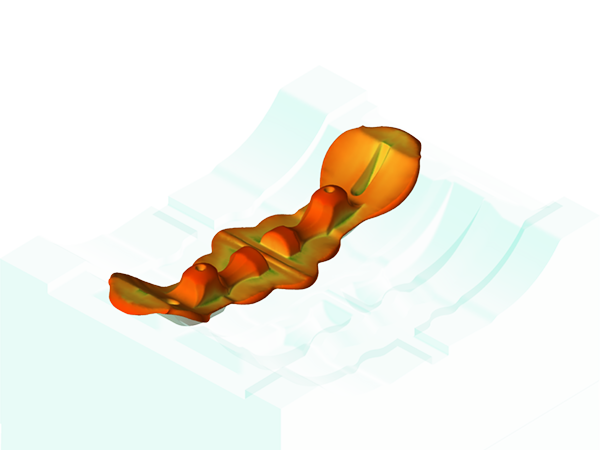

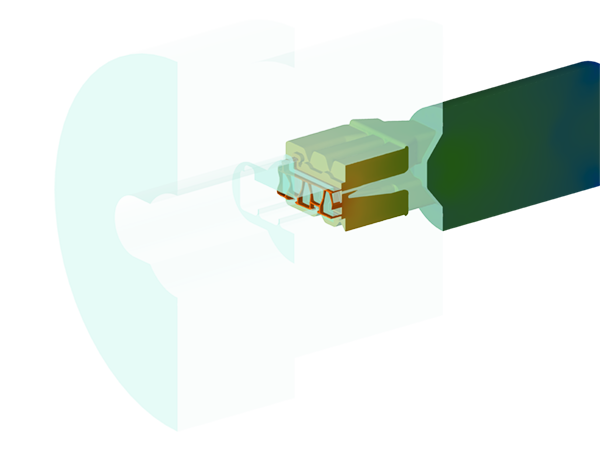

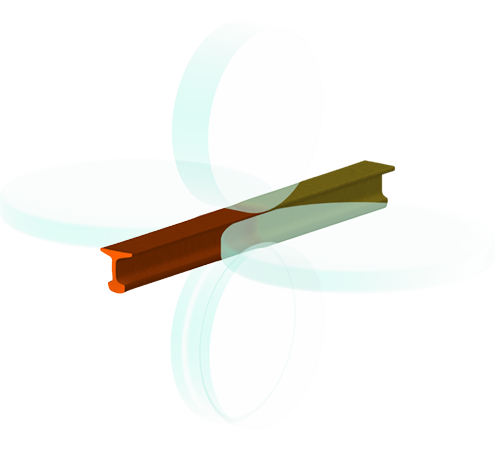

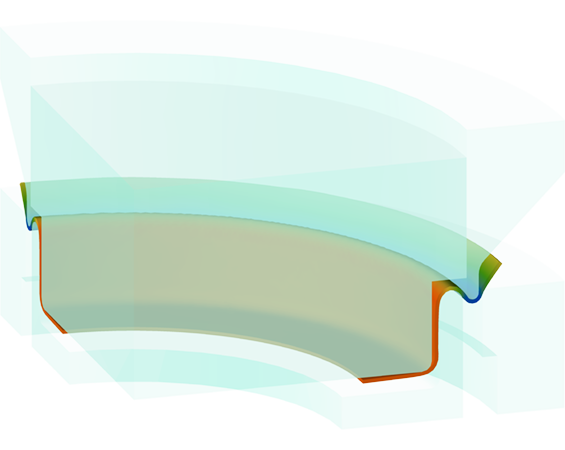

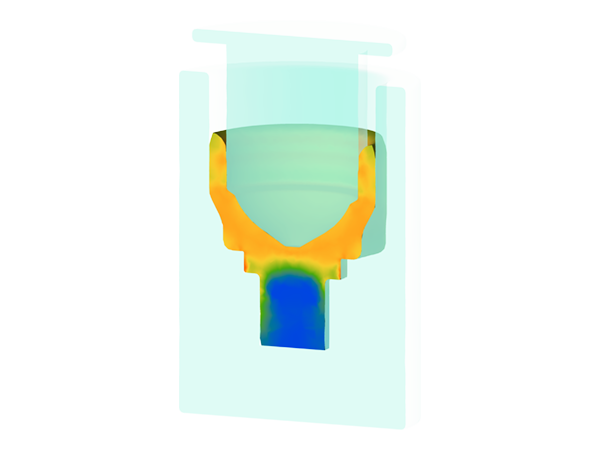

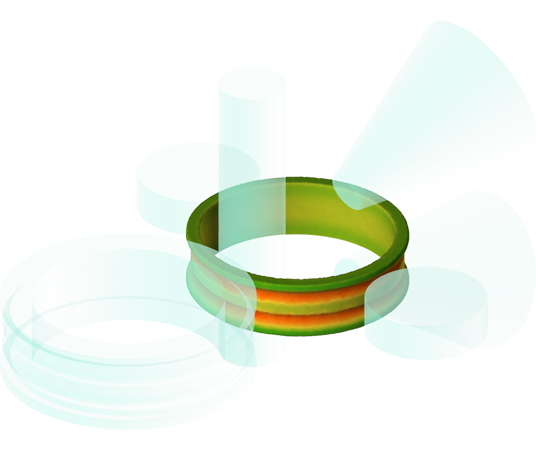

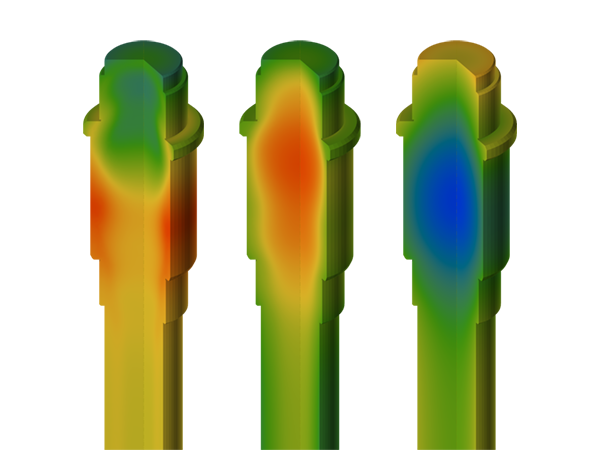

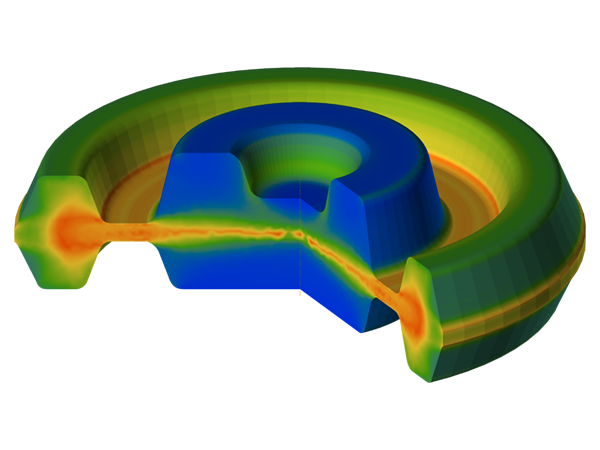

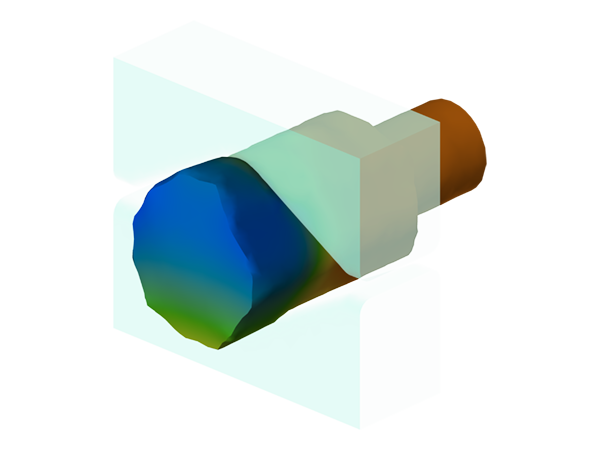

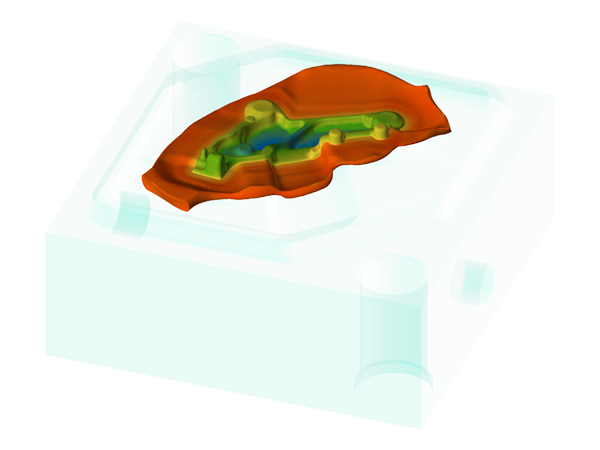

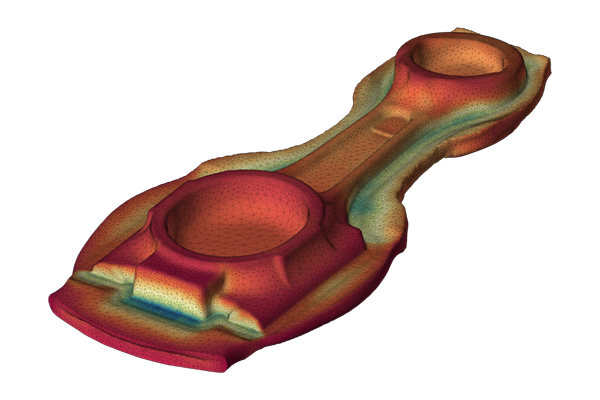

QForm UK is designed for cold, warm, and hot die forging, open-die forging, rolling, profile extrusion, and other specific metal forming processes. The software can be extended with a variety of specialized modules, including microstructure prediction, heat treatment simulation, and user-defined subroutines. A lot of advanced capabilities are implemented through a flexible API, allowing users to customize the program for specific technological tasks and research needs.

QForm UK is used for the development of a wide range of metal forming processes for parts production in the aerospace, defense, automotive, energy, aluminum extrusion, and many other industries. QForm UK combines an intuitive interface with step-by-step initial data, real-time simulation, and clear visualization of results in a separate interface window. No lengthy training is needed to simulate basic processes — get started quickly and work comfortably.

We offer a flexible licensing system that allows each user to choose the features and capabilities they need. Adapt QForm UK to your workflow, optimize costs, and get exactly the features that are most important to your business.

We are happy to provide first-class support to our customers worldwide. A valid annual license or support agreement entitles users to all major upgrades and service packs, comprehensive hotline support, access to the latest enhancements, downloads, technical resources, and the opportunity to participate actively in the global community of QForm UK users.

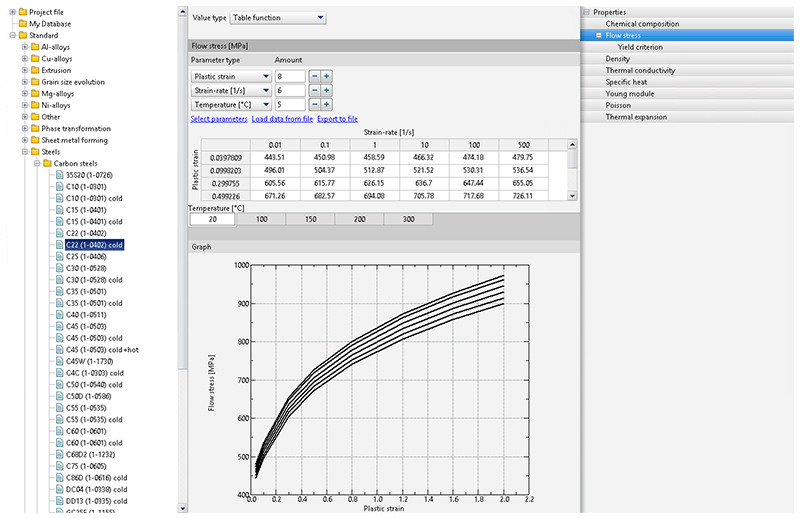

QForm UK comes with a huge database of deformed materials, tool materials, drives and lubricants. There are models of mechanical, hydraulic and screw presses, hammers, rotational equipment and several friction models specified in the program

QForm UK predicts defects, analyzes the tool's life cycle, selects equipment, and calculates material consumption. Specialized modules take into account the specifics of each individual operation — rolling, ring rolling, extrusion, sheet metal forming. The convergence of simulation results with real production data has been consistently confirmed.

QForm UK user’s manual is translated into the most popular languages and includes descriptions of all features of the program as well as many interesting examples, tutorials, and theoretical basics of metal forming processes simulation in QForm UK written in an easy-to-understand style.

QForm Group has more than 35 years of experience in software development. Our employees have M.S. and Ph.D degrees in the metal forming field. The software works in different languages and is widely used in more than 50 countries around the world by industrial plants as well as leading universities and research centers. We work to ensure that all our developed software has the best user-friendly interface and the highest accuracy of calculations. QForm UK users have confidence in the high efficiency of the program and the economic value obtained through the realistic simulations.

With the arrival of spring, we’re opening registration for our online training courses. The full schedule is now available, and everyone is welcome to join.

Why participate?

• Ask questions and interact with the trainer throughout the course

• Get a 7-day free QForm license to practice and refine your simulation skills

• Benefit from structured, in-depth content suitable for both beginners and advanced users

• Ideal for students preparing for the International Student Olympiad

As the year comes to a close, we would like to thank you for your trust, cooperation, and continued support.

Season’s Greetings! May the New Year bring health, happiness, and exciting opportunities.

We look forward to receiving your applications for participation.

The prize fund is €5,000.

Since 2014, our team has been organizing the International Students Olympiad on Metal Forming Processes. Each year, the Olympiad brings together participants from more than 15 countries, over 40 universities, and around 150 students.

The Olympiad project continues to grow, and we warmly invite you and your students to join and support this initiative!

To participate, please contact: [email protected]

The Forum is an event aimed at bringing together representatives of the global professional community — researchers, users, manufacturers, industry professionals, and early-career students — everyone interested in the development of metal forming technologies.

The Forum was attended by more than 70 participants from 50 companies. Attendance figures, a rich program of presentations and the overall atmosphere of the event give every reason to conclude that QForm Forum China was a highly successful event!

Our distributor, CAE Technology Inc., attended the annual fall conference 2025 KSTP (The Korean Society for Technology of Plasticity and Materials Processing).

At the conference, they presented a presentation titled “Optimal design of preforming and process analysis techniques for multi-material (AL–STEEL) in composite forging processes”, demonstrating the use of QForm UK Direct for preform forging.

Another important event took place in Korea, organized by our distributor CAE Technology Inc. — the CAETECH 2025 User Conference.

User conferences are among the most significant events in the professional community, where we share not only the latest developments that streamline production processes but also successful examples of QForm implementation and use.